Where Fire Meets Iron

The clang of hammer on anvil echoes through the alleyways of a Roman town. A furnace glows fiercely behind a pair of soot-covered men as they mold red-hot iron into swords and plowshares. This is a Roman blacksmith workshop in the 1st century AD, a place where practical genius met the relentless demands of empire. Here, behind the clangor and sweat, Rome’s infrastructure and military might were forged—one strike at a time.

The Blacksmith’s Role in Roman Society

Blacksmiths, or ferrarii, were essential artisans in the Roman world. They operated workshops in cities, towns, and military forts, providing tools, arms, hardware, and domestic goods. While not part of the elite, they held a respected position among tradespeople, often organized into guilds and protected under Roman law.

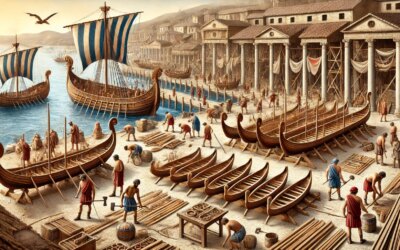

Rome’s vast reach demanded a constant supply of forged goods: weapons for soldiers, hinges for doors, wheels for carts, nails for construction. Blacksmiths were the invisible architects of daily life—providing the literal nuts and bolts of civilization.

The Layout of a Roman Smithy

Roman blacksmith workshops, usually small and attached to a domus or shopfront (taberna), featured:

- A forge or furnace—stone-lined and fueled by charcoal, kept hot with bellows

- Anvils—metal blocks used as striking surfaces

- Bellows—leather-operated air pumps to stoke the flames

- Hammers, tongs, and chisels—the basic tools of the trade

- Water troughs—for quenching and tempering metal

- Storage shelves—for raw materials, finished goods, and spare parts

Apprentices assisted by pumping bellows, preparing materials, or transporting heavy iron bars. Workspaces were smoky, loud, and intense—a blend of craftsmanship and controlled chaos.

What They Forged

Roman blacksmiths produced a wide array of metal items, including:

- Weapons: swords (gladii), spears (hastae), arrowheads, and armor fittings

- Tools: axes, plows, sickles, hammers, chisels, and knives

- Construction hardware: nails, hinges, clamps, brackets, and locks

- Household items: cooking utensils, door handles, keys, and candle holders

They also repaired broken goods, sharpened tools, and occasionally crafted ornamental pieces. Blacksmiths worked with iron, bronze, and sometimes steel, depending on the desired durability.

Military and Engineering Contributions

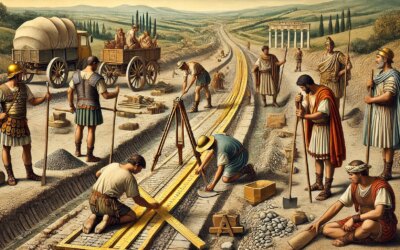

In the Roman army, mobile smiths traveled with legions, setting up temporary forges. They repaired weapons, shod horses, and maintained siege equipment. The ability to quickly produce or repair gear in the field was vital to Rome’s military dominance.

Smiths also supported the empire’s grand construction projects—roads, bridges, aqueducts—by producing the essential metal components that held everything together. Without their expertise, much of Roman engineering would have collapsed under its own weight.

Metallurgy and Technique

Roman blacksmiths understood key metallurgical processes, including:

- Smelting: Extracting metal from ore, usually done in rural workshops

- Forging: Shaping heated metal with repeated hammer blows

- Tempering: Heating and cooling to improve strength and flexibility

- Welding and riveting: Joining pieces without modern soldering

Though empirical rather than theoretical, their techniques were remarkably effective. The tools and methods they used laid the groundwork for medieval and even industrial-era metalworking.

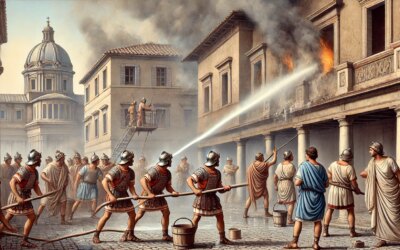

Religious and Cultural Aspects

Blacksmiths were often associated with Vulcan, the Roman god of fire and metalwork. Shrines or symbols of Vulcan sometimes adorned workshops. Some believed the blacksmith’s craft had magical qualities—transforming raw, earthly material into something useful and powerful.

Rural smiths, in particular, were seen as custodians of mystical knowledge, straddling the line between artisan and shaman in popular imagination.

Economic Status and Guilds

While individual smiths rarely became wealthy, successful workshops—especially those supplying the military or aristocracy—could earn steady income. Smiths might employ multiple apprentices and assistants, forming proto-industrial teams.

Under the empire, blacksmiths were increasingly organized into collegia (guilds), which regulated prices, training, and contracts. These institutions also offered social support, funerary insurance, and legal representation.

Legacy of the Roman Forge

The blacksmith’s forge remained central to European society well after Rome’s decline. Many of the tools and techniques used in the 1st century AD persisted through the Middle Ages, with little change. Roman methods were recorded in technical texts and taught informally for generations.

Modern archaeology has uncovered dozens of smithy sites across the empire—from Britain to Syria—each a testament to the daily labor that powered a civilization.

Metal, Fire, and Memory

Though their names are lost, the Roman blacksmiths left an indelible mark on history. In every nail driven into a bridge, every gladius raised in battle, and every tool that carved stone or tilled soil, their work lives on. Behind the glory of emperors and the grandeur of temples stood the forge—the roaring heart of an empire built by hand and hammer.